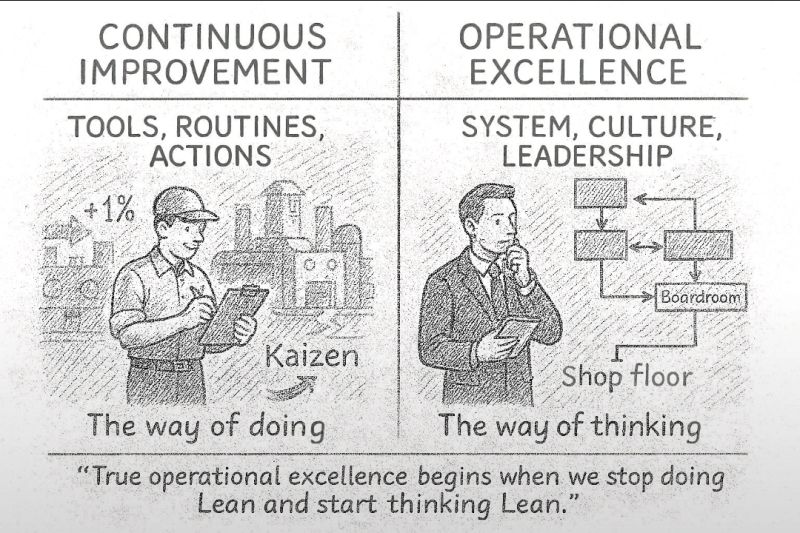

Continuous Improvement vs Operations Excellence: From the Way of Doing to the Way of Thinking

Sri Haryono, ST, MBA

Executive Board

15 December 2025

Berita dan Opini ALI Terbaru

Logistics in 2026 – 5 Top Trends

13 January 2026

The logistics industry is undergoing seismic change as 2026 approaches. Fueled by rapid technology adoption, shifting consumer expectations, demanding environmental goals, and an increasingly complex global trade environment, logistics has become much more than moving goods from point A to B. It now encompasses real-time visibility, autonomous systems, sustainable operations, and intelligent decision-making.1. AI and Autonomous Decision-Making Become Core to LogisticsOne of the most transformative trends in logistics today is the integration of AI beyond simple automation and analytics. AI systems are no longer just tools that provide recommendations. Instead, next-generation AI platforms are increasingly capable of making operational decisions autonomously.This trend also reshapes the workforce: logistics roles increasingly demand digital literacy, analytics understanding, and system oversight capabilities rather than just manual execution.2. Sustainability Is Strategic — Green Logistics RedefinedLogistics companies have moved sustainability from a compliance checkbox to a strategic imperative in 2026. With global attention on climate change and regulatory pressure increasing, logistics is evolving into a more environmentally responsible discipline.In essence, green logistics in 2026 is both an operational necessity and a market differentiator.3. Real-Time Visibility & Integrated Digital Platforms Become Table StakesCustomers and partners increasingly demand end-to-end visibility — not just at critical milestones, but continuously from origin to delivery. Real‐time tracking, sensor data, and integrated platforms are no longer optional features; they’re expected components of modern logistics.Ultimately, this trend moves the industry toward networked logistics ecosystems rather than isolated point-to-point operations.4. Last-Mile Innovation & Urban Logistics Reshapes DeliveryThe last mile is undergoing intense innovation in 2026. As e-commerce demand continues to grow, companies are rethinking how goods reach customers in cities and rural areas alike. These mixed strategies reflect the growing complexity of the last mile.5. Resilience, Risk Management & Regionalization in Global OperationsIn 2026, logistics leaders are focused on resilience — ensuring they can adapt and respond quickly to disruption. Rather than relying on extremely long global supply chains, companies are increasingly regionalizing operations:- Nearshoring and regional distribution centers help shorten transit distances, reduce risk exposure, and lower transportation costs.- Diversified supplier bases and multi-region inventory strategies provide buffers against disruptions like tariffs, port shutdowns, or trade conflicts.As 2026 unfolds, logistics is no longer a back-office function. It’s a strategic, digital, and customer-centric operation that extends from deep supplier tiers to final delivery.

👁️ 69 kali

Praktik Pembatasan Angkutan Barang Inkonsisten, Pengusaha Logistik Komplain

08 January 2026

JAKARTA, KOMPAS — Dalam masa Natal 2025 dan Tahun Baru 2026, pemerintah telah menjadwalkan operasionalisasi angkutan barang, khususnya jenis sumbu tiga ke atas. Implementasinya tidak sesuai regulasi yang ditentukan sehingga pelaku usaha logistik kembali merugi dengan penyusutan volume 15-20 persen pada Desember 2025 dibandingkan bulan sebelumnya. Kebijakan operasionalisasi angkutan barang pada masa Natal 2025 dan Tahun Baru 2026 tertuang dalam Surat Keputusan Bersama (SKB) tentang Pengaturan Lalu Lintas Jalan serta Penyeberangan Selama Masa Angkutan Natal 2025 dan Tahun Baru 2026. Namun, realisasinya, menurut pengusaha angkutan logistik, tidak sesuai aturan yang telah dibuat pemerintah sendiri. Hal ini merugikan pengusaha angkutan logistik. Berdasarkan SKB, angkutan barang bisa lewat jalan tol dan arteri dalam jendela waktu yang telah ditentukan. Namun, pada praktiknya, jendela waktu di jalan tol ditiadakan. Akibatnya, angkutan logistik akhirnya lewat jalan arteri sehingga waktu tempuh lebih lama. Persoalan lain, beberapa ruas di jalan arteri juga tidak dapat dilalui angkutan barang karena aparat melarangnya. Imbas pembatasan angkutan logistik pada Natal 2025 dan Tahun Baru 2026, volume penjualannya turun sekitar 20 persen pada Desember 2025 dibandingkan bulan sebelumnya. Ini mencakup barang konsumsi dan elektronik. Akhir tahun semestinya dapat menjadi musim puncak untuk menutup rendahnya volume dan pendapatan pada yang kurang optimal pada bulan-bulan sebelumnya. Hilangnya momentum karena volume yang rendah, otomatis pemasukan pun menyusut, sehingga setoran pajak juga tidak optimal. ”Jadi, kan, perlu kita telusuri ya. Ini bisa jadi lesson learned buat berikutnya. Sebentar lagi Ramadhan. Pelaku usaha industri sudah curi start. Mereka sudah produksi sebulan sebelumnya,” kata Mahendra. Ia mendesak agar seluruh pemangku kepentingan, terutama pemerintah, melihat dari berbagai sisi atau menggunakan helicopter view. Ada aktivitas logistik nasional yang rutin dilakukan. Namun, masalahnya selalu berkutat di tempat yang sama dan belum ada solusinya. SKB yang selama ini disusun tiga instansi semestinya turut melibatkan Kementerian Perindustrian, Kementerian Perdagangan, dan Kementerian Keuangan. Instansi-instansi tersebut dapat memberikan perspektif dari sisi pelaku usaha. Lagi pula, masih ada moda transportasi lain yang semestinya bisa dibantu untuk mendukung angkutan logistik tetap berjalan. Pemerintah dapat menyiapkan kapal roll-on/roll-off (roro) untuk mengakomodasi angkutan logistik. Ada ruas jalan tertentu yang bisa digunakan khusus bagi angkutan logistik. Wakil Sekretaris Jenderal Asosiasi Pengusaha Truk Indonesia Agus Pratiknyo mengatakan, pembatasan operasional angkutan jalan mendorong para pengusaha di daerah saling berkoordinasi. Sebab, kepolisian di beberapa wilayah berhak melakukan diskresi sehingga kesempatan itu dimanfaatkan untuk menggelar operasi. ”Pelarangan full itu memberatkan dan membingungkan kami sebagai pengusaha karena kami kerja terjadwal. Customer kami harus menyesuaikan dengan pengiriman. Kalau sekarang ini regulasi dibuat mendadak, ini tidak baik untuk dunia usaha karena jadi ekonomi berbiaya tinggi,” tutur Agus. Ia juga menyebut, ada penyusutan volume pengantaran 15-20 persen pada Desember 2025 dibandingkan sebulan sebelumnya. Otomatis, omzetnya pun tergerus. Jika mewajibkan pembatasan angkutan logistik, pemerintah perlu bersikap adil dengan memberikan solusi atau stimulus bagi pengusaha. Ia merasa, pemerintah belum memperhatikan sektor angkutan logistik. ”Berikan stimulus, entah keringanan pajak kendaraan, dan sebagainya. Itu pengeluaran kami sebagai kewajiban ke negara. Jadi harus berimbang (timbal-balik), ada kompensasi. Sekarang (pemerintah) hanya bisa melarang,” kata Agus. Meski demikian, Ketua Umum Gabungan Perusahaan Ekspor Indonesia Benny Soetrisno menilai, pelaksanaan Natal 2025 dan Tahun Baru 2026 sudah jauh lebih baik dibandingkan larangan angkutan barang saat Lebaran. Alasannya, tidak terjadi kemacetan di Pelabuhan Tanjung Priok. Namun, ia berharap, pemerintah tetap perlu berkoordinasi dengan pelaku ekspor-impor untuk mengatur lalu lintas angkutan barang. Evaluasi pembatasan angkutan Menteri Perhubungan Dudy Purwagandhi menyatakan, jendela waktu diberikan guna mengakomodasi pelaku usaha angkutan logistik agar tetap beroperasi selama masa libur. Namun, ada kekhawatiran beroperasinya kendaraan besar akan mengganggu jalannya pelaksanaan Natal dan Tahun Baru. ”Setelah kami evaluasi, sepertinya window time ini kurang efektif karena akhirnya dalam pelaksanaannya arus kendaraan logistik cukup besar sehingga dikhawatirkan akan mengganggu kelancaran maupun keselamatan pengguna jalan,” tutur Dudy seusai menutup Posko Natal 2025 dan Tahun Baru 2026 di Jakarta, Senin (5/1/2026). Beroperasinya kendaraan besar dinilai tidak memberi jaminan rasa aman dan keselamatan di jalan raya. Sebab, ada risiko kecelakaan di jalan raya saat mobilitas masyarakat tinggi. ”Kami akan melakukan evaluasi dari Natal dan Tahun Baru kemarin, kemudian juga Lebaran. Pada bulan Januari, kami harapkan sudah bisa memberikan keputusan bagaimana mekanisme pengaturan transportasi logistik, khususnya yang ada di jalan,” ujar Dudy. Pembatasan angkutan barang ini merupakan upaya pemerintah mengatur sekaligus mengurai kepadatan lalu lintas. Hal ini biasa dilakukan bersamaan dengan kebijakan bekerja dari mana saja atau work from anywhere untuk memecah keramaian. Ketika ditanya skema pembatasan penuh apakah akan berlaku pada masa Lebaran mendatang, Dudy belum dapat memastikannya. Sebab, kebijakan itu akan diberlakukan berdasarkan proyeksi pergerakan masyarakat. ”Namun, kalau nanti pada Lebaran volumenya akan lebih meningkat, tentunya kami akan lebih strict terhadap pemberlakuan pembatasan (angkutan logistik). Yang penting dan perlu diingat, prioritas utama kita adalah keselamatan. Kami minta pengusaha harus memaklumi, secara keselamatan, kita enggak bisa menguantifikasi nyawa manusia,” tutur Dudy. Pemerintah berjanji akan mendengarkan aspirasi pengusaha angkutan logistik. Ia juga akan melibatkan para pengusaha angkutan logistik dalam penyusunan kebijakan pembatasan kendaraan besar. Sebelumnya, pemerintah telah menerbitkan SKB tentang Pengaturan Lalu Lintas Jalan serta Penyeberangan Selama Masa Angkutan Natal 2025 dan Tahun Baru 2026. Regulasi itu diteken Kemenhub, Kementerian Pekerjaan Umum, dan Korps Lalu Lintas Polri. Pembatasan operasional angkutan barang meliputi angkutan barang dengan tiga sumbu atau lebih, kereta tempelan atau kereta gandeng. Angkutan yang dibatasi, khusus membawa hasil galian (tanah, pasir, batu), hasil tambang, serta bahan bangunan, seperti besi, semen, dan kayu. Berbeda dari pembatasan sebelumnya, keberadaan jendela waktu memberi peluang bagi angkutan logistik untuk bergerak. Hal ini membedakan dari pembatasan pada periode-periode sebelumnya. Pembatasan dimulai pada 19 Desember 2025 hingga 4 Januari 2026. Dalam rentang waktu tersebut, setidaknya ada enam hari angkutan logistik diberi kesempatan beroperasi, yakni pada 21-22 Desember 2025 dan 29-31 Desember 2025. Artinya, pembatasan akan berlaku pada 19-20 Desember 2025, 23-28 Desember 2025, serta 2-4 Januari 2026. Pembatasan pada jalan tol akan dilakukan secara penuh pada pukul 00.00-24.00 WIB. Pembatasan lebih fleksibel pada jalan arteri berlaku pukul 05.00-22.00. Setarakan kepentingan Menurut Wakil Ketua Umum Masyarakat Transportasi Indonesia IB Ilham Malik, pembatasan angkutan logistik selalu jadi isu berulang karena Indonesia belum menempatkan angkutan logistik sebagai bagian sistem pelayanan publik strategis. Angkutan logistik masih dianggap sebagai ”pengganggu” lalu lintas saat puncak mobilitas. Padahal, secara fungsi ruang dan ekonomi, logistik merupakan urat nadi yang justru menopang stabilitas harga, ketersediaan barang, dan keberlanjutan aktivitas masyarakat selama hari besar. SKB pembatasan kendaraan merupakan upaya jalan tengah yang diberikan pemerintah melalui mekanisme jendela waktu. Negara sebenarnya mengakui setaranya kepentingan keselamatan pemudik dan kepentingan distribusi barang. ”Ketika implementasi window time dihilangkan sepihak dan tol ditutup penuh, maka yang terjadi bukan sekadar persoalan teknis lalu lintas, melainkan kepastian kebijakan. Pengusaha logistik sudah menyusun jadwal, biaya, kontrak berbasis SKB,” tutur Ilham. Ketika aturan yang diterbitkan pemerintah tidak dijalankan konsisten, maka risiko ekonomi otomatis dialihkan ke pelaku usaha. Namun, alasan keselamatan tentu tidak bisa diabaikan. Jalan tengahnya, Ilham melanjutkan, perlu disusun lebih sistemik. Jendela waktu harus dirancang sebagai skema operasional, bukan sekadar klausul kebijakan. Ada ruas tol tertentu yang dibuka terbatas dengan pengawalan, kecepatan maksimum rendah, dan jadwal ketat yang harus dipatuhi. Kemudian, pendekatan tata guna lahan perlu dipertimbangkan. Ketergantungan penuh pada koridor tol utama menunjukkan lemahnya persebaran pusat logistik, pelabuhan kering (dry port), dan jalur distribusi alternatif. ”Selama kebijakan Natal dan Tahun Baru masih bersifat reaktif—menutup ketika padat, membuka ketika lengang—maka isu ini akan selalu muncul lagi ke depannya. Yang dibutuhkan segera adalah perencanaan mobilitas libur panjang yang integrasikan pergerakan manusia dan barang sebagai satu sistem, bukan dua kepentingan yang saling mengorbankan,” ujar Ilham. Sumber: https://www.kompas.id/artikel/implementasi-tak-sesuai-regulasi-pengusaha-angkutan-logistik-kembali-merugi

👁️ 42 kali

Pembatasan Truk Tekan Volume Pengiriman Logistik Saat Nataru 2025/2026

05 January 2026

KONTAN.CO.ID - JAKARTA. Asosiasi Logistik Indonesia (ALI) menyebut adanya penurunan volume pengiriman pasca diberlakukannya pembatasan pergerakan truk sumbu tiga atau lebih; truk dengan kereta gandengan/tempelan; serta kendaraan barang pengangkut galian, tambang, dan bahan bangunan saat nataru 2025/2026. Ketua ALI, Mahendra Rianto mencatat, penurunan volume pengiriman pada sejumlah anggota asosiasi berada di kisaran 20% hingga 25%. Menurutnya, terdapat dua faktor utama yang memicu kondisi tersebut, yakni keterlambatan pengiriman ke pelabuhan internasional serta keputusan pelaku usaha untuk menunda pengiriman hingga masa pembatasan berakhir. “Jadi daripada kena biaya karena harus menerabas aturan itu, di sana juga kena biaya tambahan transit di Singapura, jadi mereka menahan (pengiriman),” jelas Mahendra kepada Kontan, Jumat (2/12/2026). Kata Mahendra, penurunan ini tak terjadi pada tahun 2024. Pada periode tersebut, perusahaan logistik masih memilih untuk tetap melakukan pengiriman seperti biasa meski terdapat pembatasan. Namun, tingginya biaya tambahan yang harus ditanggung membuat strategi tersebut tidak lagi dipilih pada tahun 2025. Tak hanya bagi perusahaan logistik, Mahendra melihat kerugian ini juga terasa pada pabrik-pabrik di sektor industri tertentu seperti elektronik dan fast moving consumer goods (FMCG). “Karena dia kan produksinya masif dan timeline pengiriman harus sesuai rencana untuk dikirim ke daerah-daerah distribusi secara berkala. Enggak mungkin dia kirim sekaligus sebanyak-banyak-nya apalagi sekarang musim hujan, tidak bisa ditaruh di luar lama-lama,” terangnya. Oleh karena itu,, ALI berharap pengaturan arus rantai pasok dan logistik saat nataru maupun hari raya keagamaan dapat dilakukan secara lebih berimbang dan tidak diskriminatif. Mahendra menilai seluruh pihak memiliki kepentingan yang perlu diperhatikan pada momen tersebut, termasuk pemerintah yang harus menjaga penerimaan negara. “Jadi negara ada kepentingan juga untuk bisa mencapai target pajak, bea masuk, dan sebagainya. Kita sebagai pelaku tentunya menunggu kebijakan yang lebih berpihak juga kepada logistik dan rantai pasok,” pungkas Mahendra. Beruntungnya, dampak dari pembatasan ini tak terasa di Lion Parcel. Chief Marketing Officer Lion Parcel, Kenny Kwanto, mengaku bahwa regulasi ini tak mengganggu distribusinya lantaran perusahaan menggunakan kombinasi moda transportasi yang tak termasuk dalam kategori kendaraan yang dibatasi. “Operasional kami tetap berjalan normal, sehingga arus pengiriman kami tetap terjaga,” ucap Kenny kepada Kontan, Jumat (2/2/2026). Untuk memastikan kelancaran layanan selama periode puncak, Lion Parcel juga melakukan koordinasi intensif dengan seluruh mitra, memastikan kesiapan armada, menyesuaikan jadwal, serta mengoptimalkan perencanaan rute sebelum peak season dimulai. “Ini adalah upaya kami untuk memastikan layanan kepada pelanggan tetap berjalan optimal meskipun terdapat lonjakan pengiriman,” pungkas Kenny. Sumber: https://industri.kontan.co.id/news/pembatasan-truk-tekan-volume-pengiriman-logistik-saat-nataru-20252026

👁️ 30 kali